Share

Author

George Anderson

Share

Updated July 1, 2022

As more and more B2B buyers turn to online distributors to buy spare parts, manufacturers are encountering a problem. They’re losing business. Why? To put it simply, if you’re not selling online, it’s easier to buy equivalent parts from someone else. That’s especially true if you aren’t offering visual parts ordering with interactive, exploded diagrams.

Clearly, then, manufacturers must define a spare parts strategy for the digital age. Here are 4 factors to consider as you define yours.

Your spare parts buyers want to shop online

Here’s what leading market research says about B2B buyer preferences:

- 43% of B2B buyers want to buy from you, the manufacturer, rather than a distributor. (Forrester Research)

- 49% of companies now make 50-74% of all corporate purchases online. (DigitalCommerce360)

If you manufacture spare parts for a B2B market, your parts strategy must take this into account. It’s critical to consider these trends and how they’re affecting your business right now.

Why? Because those effects will only grow as more and more B2B companies offer online ordering, and your end users want the easiest purchasing experience they can get. Chances are, your competition is already giving it to them with self-service ecommerce that doesn’t require a call to a CSR (customer service representative).

On that note, let’s talk about your spare parts competition.

Two kinds of online competition are undercutting spare parts sales

If you’re still making your customers look up spare parts in a print catalog, you’re most likely losing sales from two kinds of competition. Both of these alternatives are available online, 24×7, at your customers’ convenience.

- A 3rd party manufacturer selling equivalent spare parts online. Your buyers may not care whether the parts are authentic OEM or not. If competing parts are easy to buy online, you risk losing the sale if your strategy for selling spare parts doesn’t include a web channel.

- Your distributor substitutes a competing part for yours. If your distributor is out of stock on your part, their ecommerce catalog may automatically suggest an equivalent part from a competing manufacturer. Why wouldn’t they? They just want the sale, regardless of who manufactured the part. You have no control over the sale, and you miss out on an opportunity, even though you have plenty of inventory yourself.

In both these cases, the buyer’s desire for convenience can lead to a lost sale for you. This is especially true for highly commoditized and non-branded spare parts.

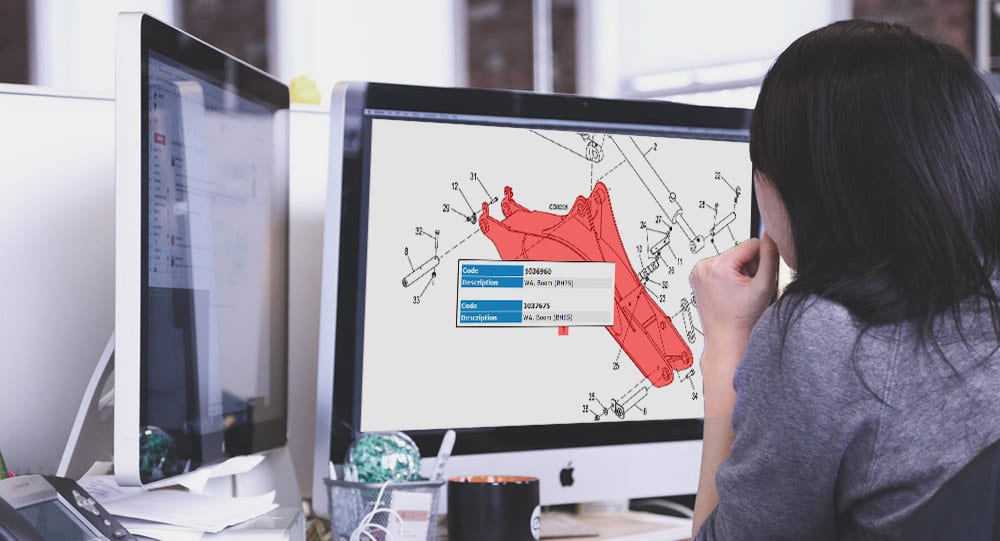

The solution? Interactive visual diagrams with live SAP data. This lets your customers choose the right part on their own, then order it, with the order posting to SAP in real time.

You may be missing out on a spare parts opportunity in B2C

Not all spare parts manufacturers have an opportunity in B2C. However, for those that do, ecommerce with visual parts ordering offers a tremendous opportunity—and your parts strategy should take account of that fact.

For example, if you sell lawn mower parts, chances are you currently sell to distributors or dealers. Those intermediaries sell your parts to the end user (the B2C consumer). Why not sell direct and launch a B2C channel? This offers you all kinds of opportunity for new revenue growth—typically at a higher margin than your sales to distributors.

Even if B2C doesn’t apply to you, there’s one more factor we need to talk about. It’s your cost of processing spare parts orders.

There’s a more efficient (cheaper) way to process spare parts orders

Every factor we’ve talked about so far is on the front end of the business—either defending existing revenue, or going out and getting new revenue. But when you launch a spare parts solution with click-to-order exploded diagrams, you see a a backend benefit, too. You become more efficient by eliminating the order gap (the need for CSRs to rekey orders in SAP).

I once worked for a spare parts distributor, so I know how this goes. As a CSR, I had one software system for spare parts lookups, and another system for order placement. For every customer I helped, I was on the phone for several minutes to half an hour. After drilling down to what the customer needed, I had to copy and paste that SKU number into the order system.

Sounds simple, but scale that up to a whole organization, and it’s pretty inefficient.

This is where a spare parts ordering system reduces your cost of order fulfillment. When you give your customers self-service exploded diagrams with 1-click add-to-cart, they can find the machine they’re servicing and visually select the right part—without a phone call. That alleviates your customer service staff from doing tedious manual order entry.

Want to become Easier To Do Business With?

Check out Corevist Commerce Cloud.

Managed B2B portals and eCommerce with prebuilt integration for ECC and S/4HANA.